The wire drawing is a kind of metal processing process. In metal pressure processing, the metal is forced through the mold by external force, and the metal cross-sectional area is compressed. The technical processing method of obtaining the required shape and size of the cross-sectional area is called metal drawing process. The machine used for this metal processing process and changing the shape and size of metal wires is called metal wire drawing machine.

Types Of Wire Drawing Machines

According to the different types of wire drawing machines, we roughly divide wire drawing machines into the following categories:

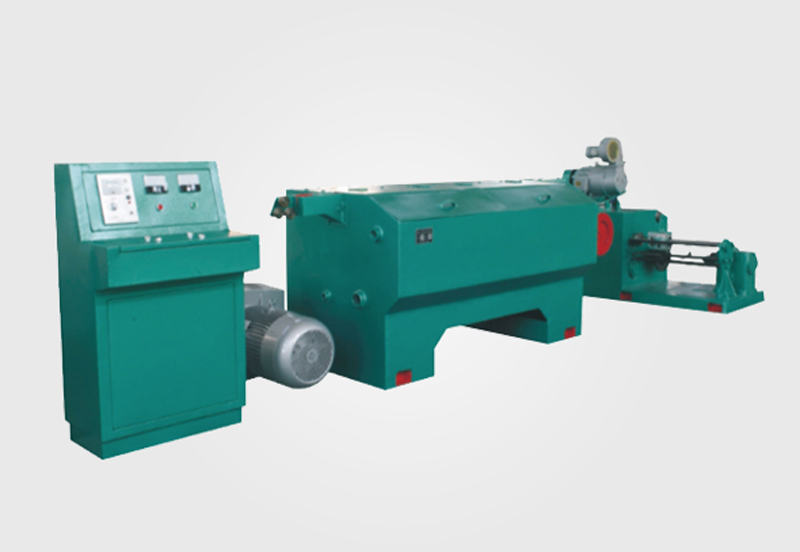

Pulley Wire Drawing Machine

Pulley wire drawing machine is the most widely used wire drawing machine. Because during wire drawing, the wire pass each drum will also pass through a pulley. Pulley type wire drawing machine has the characteristics of simple structure, easy operation and low maintenance, high efficiency and low consumption production mode. Therefore, it is suitable for processing various metal wires of medium and fine specifications. The drawing steel wire is generally 2-8mm.

The pulley wire drawing machines produced by our METAL TECH have the features that the machine body adopts integral steel plate welding, and the thickness of steel plate reaches 14mm, which makes the machine more solid and stable during operation. All our machines are equipped with hard tooth surface and silent high-speed reducer. Compared with the belt transmission used in most other factories, the advantage of our reducer transmission is that it is quieter, faster, more torque and more durable (the belt is easy to be damaged). The whole machine adopts the electrical control, which is more intelligent and advanced.

pulley wire drawing machine

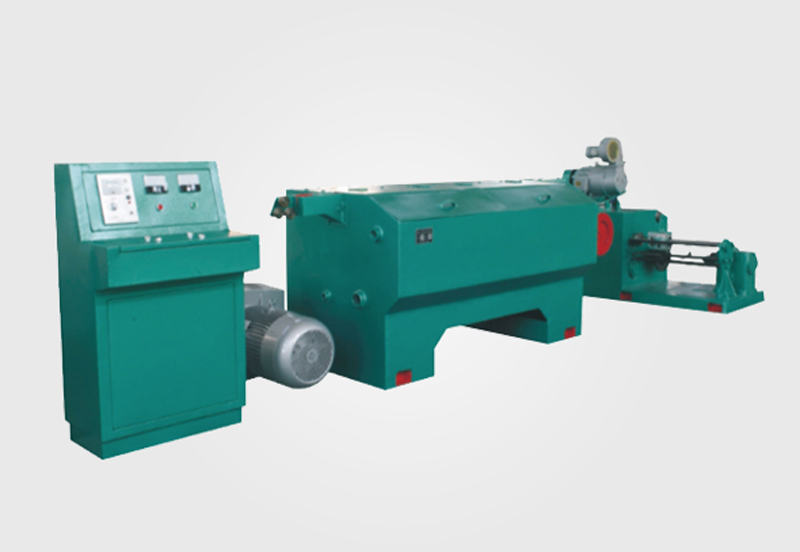

Straight Line Wire Drawing Machine

Compared with the Pulley type wire drawing machine, the straight line wire drawing machine eliminates the process of passing through the pulley, so that the wire can directly pass through each drum, greatly improving the drawing speed. The fastest speed can reach 1200 meters per minute. The whole machine adopts the electrical control, which is more intelligent and advanced,It also saves labor costs.

straight line wire drawing machine

Water Tank Wire Drawing Machine

The water tank wire drawing machine has a water tank, which is filled with water, so it is called water tank wire drawing machine or wet wire drawing machine. The water tank wire drawing machine is a small continuous production equipment composed of multiple drawing heads. By drawing step by step, and placing the drawing heads in the water tank, finally the metal wire is pulled down to the required specifications. The working principle of water tank drawing machine is that after the metal wire passes through each stage of drawing in the machine, the wire diameter of the metal wire changes, so the working line speed of each drawing head should also change. The water tank wire drawing machine is suitable for drawing various metal wires of medium and fine specifications, especially suitable for drawing medium and low carbon steel wires, galvanized iron wires, bead steel wires, hose steel wires, tungsten, molybdenum, steel cords and copper wires and aluminum wires. The water tank type wire drawing machine is mainly used for drawing fine wires less than 3mm, and the minimum wire diameter can reach 0.1mm

wet wire drawing machine

Vertical Wire Drawing Machine

The vertical wire drawing machine has only one drum, which is mainly used to draw thick wire with a wire diameter of more than 8mm, and the maximum wire diameter can reach 40mm.

vertical wire drawing machine

EN

EN

fr

fr  es

es  ru

ru  pt

pt  ar

ar  vi

vi  th

th  pl

pl  ro

ro